The goal : measure the RPM of an home-made electric motor for a school experiment.

Requirements

The kind of motor built for the experiment is slow by definition, so the RPM meter (also called tachometer -

http://en.wikipedia.org/wiki/Tachometer) must be capable to measure and display low revolutions per minute.

The other goal is to build the tool easily and in short time, possibly spending the less possible.

Acquiring Methods

The first problem to solve is how to acquire the rotor revolutions, i.e. how to translate a movement in an electric signal.

Usually there are two methods :

Magnetic

Since the rotor has already magnets glued on it, it is relatively easy to add a magnetic sensor capable to generate a pulse every time a magnet pass close to it.

The sensor can be a reed switch or, typically, a Hall sensor. The Hall sensor is better than the Reed switch because is not mechanical, so is not generating false signals and is faster.

If an Hall sensor is used, it must be unipolar.

There are two kind of Hall sensors, unipolar and bypolar.

The bypolar requires to "see" a change pole. i.e. a change from South pole to North pole and viceversa. Every change, triggers the change of the electric signal.

The unipolar sensor change the state of the electric signal every time a South pole is close to the sensor.

Here a graph to show the two kind of Hall sensors :

The upper part shows a bipolar Hall sensor.

When the South pole is close to the sensor, the output signal goes down. Only when the North pole is close to the sensor, the output signal goes back high.

The lower part of the graph shows a unipolar Hall sensor.

When the South pole is close to the sensor, the output goes down and it goes up as soon as the South pole is going away from the sensor.

Optical

The other common way to acquire the revolution, is optical.

Typically on the rotor is glued a reflective surface in a spot. A Infrared ray is sent toward the rotor and a circuit can detect the reflection of the infrared ray when bounced back from the reflective surface.

As alternative is possible to attach a disc with holes to the rotor and have a light beam (or infrared beam) interrupted by such disc.

A third optical alternative is to attach to the rotor a "black and white" pattern and illuminate it with a stroboscopic light.

Changing the frequency of the light until the pattern is "stable" (or visible as it would be stopped) will give the RPM.

Measurement

We have a series of pulses generated by the sensor.

Let assume we are using the magnetic acquiring method, with a unipolar Hall sensor.

Depending how many magnets we have on the rotor we can have "n" pulses for every revolution.

i.e if we have two magnets on the rotor, we'll have two pulse every revolution. 4 magnets will generate 4 pulses and so on.

The "intuitive algorithm is quite easy. We need to count the number of pulses in a minute, then divide the number for the number of magnets and the result will be our RPM.

Unfortunately this method has a drawback. We need to wait a minute before to see the result and after that, we need to wait another minute before to see changes.

So we need to reduce the acquiring time and then estimate the RPM from the minor number of readings.

For example we can count the pulses for 1 second, then divide the number of pulses by the number of magnets. The number will represent the number of revolution for second. If we multiply that number for 60, will have the number of revolution per minute (1 minute = 60 seconds).

This can work well assuming the motor rotates at a constant rate and that rate is not too slow.

For very slow rotations, it is necessary to increase the counting time, maybe to two or three seconds (and then multiply accordingly)

The problem with that is the "visualization" of the measurement. More time to count the pulses means more time between the visualization of the result.

Building

It is possible to build the tachometer in many different ways.

Of course today is more simple to use a microcontroller rather than use more "traditional" ways, like using counters, decoders and LED display.

Any microntroller family is more than suitable for this application, especially because the measurements to do are not critical.

A microcontroller is also better than "traditional logic" because it require less components and only changing the software is possible to change the type of measurement.

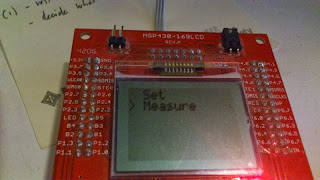

Mostly because is something I already have around, the idea is to use the Texas Instrument MSP430 family of microcontroller, specifically a board with already the

MSP430F169 and a Philips LCD display.

This board has everything we need to build a tachometer and we can easily change the parameters, like the number of magnet on the rotor and the acquisition time.

The software will be build using the GNU Msp430 Gcc compiler.

Note ! It is possible to use the software on different boards with few modifications.

For example the MSP430 Launchpad board is more than enough for this project.

Only two reasons did let me decide for the Olimex board :

- I already had this board around picking up dust

- This board has already a joystick and LCD display on it

Tools

In order to develop the RPM meter (or tachometer) some tools are necessary.

The software will be build under a Linux machine, using

Code::Blocks as editor/IDE.

The compiler used is the open source version of the

GNU Gcc for the MSP430 .

The debug system is based on the msp430-gdbserver.

An oscilloscope will be used to check the input signal from the Hall sensor.

The PC used to develop the code must have a traditional parallel port since the only GDB tool is parallel.

For the schematics, the

FidoCad and

Eagle programs will be used.

FidoCad allows to draw very simple schematics, Eagle is more sophisticate and can be used to produce a PCB (not necessary for this particular project though)

Hardware

As introduced before, the main hardware is the Olimex board based on the MSP430F169.

What is needed is the Hall sensor. I choose a Honeywell SS400 series Unipolar Hall sensor (

SS441A ).

The sensor will be connected to an I/O pins of the board, one capable to read the output signal from the sensor.

Since the board has plenty of available I/O Pins is not a problem.

Specifically will be used the Pin1.1 to read the signal from the Hall Sensor.

The P1.1 is capable to generate interrupts and it can be also connected to an internal timer in case a different measure approach is needed.

The sensor needs to be powered with a Vcc starting from 3.8 V. The Olimex board is operating at 3.3.V so an external regulator is needed and a 5V one is used. Because the MSP430F169 I/O pin are NOT 5V tolerant a resistor limiting the current is needed to avoid damage to the microcontroller.

The capacitors are the standard ones for the 78L05 regulators.

Here is possible to find the schematic of the Olimex board.

Software

First draft

The software is a first simple draft to prove the concept and verify the hardware.

It is based on the original demo code coming with the board, modified for the specific needs.

The Hall sensor signal will be connected to an interrupt capable I/O in order to don't miss any "firing" of the signal.

One or more timers will be used for the time counting. The visualization will be placed in the main loop.

The algorithm is quite simple and based on two interrupts.

One interrupt is related to the I/O pin connected to the Hall sensor. Normally the signal is pulled up, so the interrupt is set to fire on the descending slope of the signal.

The interrupt function increment a counter every time the signal goes down.

The other interrupt is a timer.

A generic timer "fires" every "n" seconds (default is 1).

When the timer fires, the the counter is copied in a variable and the counter is set to zero.

A flag is set to one indicating the need to display the content.

In the main loop, the visualization loop check the variable updated by the visualization timer to show the result.

I/O Settings

Some I/O are "forced" by the nature of the board.

Here the main ones used other than the ones pre-wired on the board :

P1.1 Hall sensor input

Pulled up, the pin goes to zero when a South Pole magnetic field is close to the sensor

P2.1 Status LED - toggle at every Hal sensor signal

The LED is toggled at every sensor magnetic event

P2.2 Status clock

The pin is toggled at every timer firing. If the timer is set for 1 second, the signal will have 2 second period.

2 seconds timer will generate a 4 seconds period on the pin and so on.

P2.3 Debug pin

Generic debug pin

Clock settings

The Olimex MSP430F169 LCD board has two crystal sources.

A 32Khz crystal and a 8 Mhz crystal.

For this application one of them should be OK since the low time involved.

The minimum period needed is about 1 second, so also the slower but precise 32Khz source should be OK as clock.

In order to minimize the timer interrupts generated, the 32 Khz crystal is used in order to generate a 1 second timer used for the measurement, the rest of the board continue to use the DCO as main source of the clock.

To set the 32Khz crystal :

DOCTL = 0x60

modulation off, DCOx and RSELx ~800kHz

BCSCTL1 = 0xB7

XT2OFF = 1 - XTS = 0 - DIVAx = 3 - RSELx = 7

BCSCTL2 = 0x00

SELMx = 0 - DIVMx = 0 - SELS = 0 - DIVSx = 0 = DCOR = 0

BCSCTL3 = 0x0C

XT2Sx = 0 - LFXT1Sx = 0 - XCAPx = 12.5pF - XT2Of = 0 - LFXT1OF = 0

With this setting the ACLK is of 4096 Hz, the MCLCK/SMCLK of ~800kHz

Note : using the 32Khz for the main clock (MCLK) the display is not working properly.

Timer setting

A generic timer is handling some sub-timers used to count the Hall sensor pulse and display the value.

The timer_A 0 will be used in the up mode.

The clock source for the timer will be ACLK, i.e. 4096 Hz.

The Timer_A will be set with a /8 so that the value 512 placed in the TACCR0 will generate an interrupt every 1 second.

TACTL = TASSEL_1 + ID_3 + MC_1; /* Uses ACLK, divide by 8, count in up mode */

TACCTL0 = CCIE; /* Use TACCR0 to generate interrupt */

TACCR0 = TMRVALUE; /* 1s */

Menu

When the code starts, a menu appears.

Two choices are available :

The Set allows to set up some parameters, like the number of seconds for the counter/display value or the number of magnets

The Measure starts the measurement.

Update

After few small modifications and settings, the tachometer was installed on the home-made experiment motor.

The sensor is placed on the top of the rotor using a wooden pole, so to be perfectly aligned with the rotor's magnets.

If somebody is interested to have the source code just contact me